pitch screw vacuum pump

-

Hot

Screw Vacuum Pump

Screw vacuum pump is a pumping equipment that uses a pair of screws to perform synchronous high-speed reverse rotation in the pump housing to produce suction and exhaust effects. It is an updated product of oil-sealed vacuum pump, which can remove gases containing a large amount of water vapor and a small amount of dust. It is widely used in domestic pharmaceutical, chemical, semiconductor and other enterprises with high requirements for clean vacuum.

Email Details -

Hot

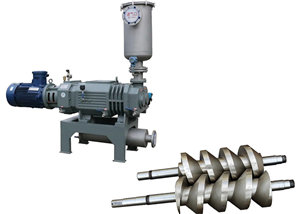

Variable Pitch Screw Vacuum Pump

Summarize

Email Details

Variable pitch screw vacuum pump is the use of gear drive synchronous reverse rotation of the mutual mesh without contact with the left screw and the right screw for high-speed rotation, the use of pump shell and mesh helix to separate the spiral groove into a number of Spaces, the formation of a number of stages, the gas in the various grooves (column deformation pitch) for transmission movement. The two screws are finely balanced, supported by bearings, and installed in the pump shell. There is a certain gap between the screw and the screw, and the screw and the pump body. There is no friction between the pumps when they work, smooth operation, low noise, and no lubricating oil in the working chamber. It can completely replace oil-sealed mechanical pump and water-sealed mechanical pump to become a new generation of main vacuum acquisition equipment. -

Hot

Equidistant Pitch Screw Vacuum Pump

Summarize

Email Details

Screw type oil-free mechanical vacuum pump, also known as dry screw vacuum pump, is the use of gear transmission synchronous reverse rotation of the mutual mesh without contact with the left screw and the right screw for high-speed rotation, the use of pump shell and mesh helix will be separated into a number of Spaces, the formation of a number of stages, the gas in the equivalent of each groove (cylindrical pitch) for transmission movement. The two screws are finely balanced, supported by bearings, and installed in the pump shell. There is a certain gap between the screw and the screw, and the screw and the pump body. There is no friction between the pumps when they work, smooth operation, low noise, and no lubricating oil in the working chamber. It can completely replace oil-sealed mechanical pump and water-sealed mechanical pump to become a new generation of main vacuum acquisition equipment.